Software WaM-MCS

The WaM-MCS (Machine Control Software) is completely developed by WaM. The software is written in C# and Windows based. The communication backbone is EtherCAT (Beckhoff) or ProfiNET (Siemens) to integrate servo motors, pneumatic valves/cylinders and digital I/O.

The software could be used to program all type of WaM winding machines and autolines, as well as third party machines, f.e. for Retrofit. WaM sells the software also as separated product for all kind of machines. The user interface is extremely flexible and fast and can be adapted to all kind of requirements. The language and the password can be modified.

For fast process optimization, you can adjust axis speed 1-100% in automatic mode, incl. the function "brake point" for program modification.

The writing of applications and use of routines can executes complex operations and be defined by names. It also allows to use multiple parallel processes. Specified winding functions like wrapping, winding, etc. are pre-installed. The movement of axis is extremely fast because of chained axis interpolation and reduced inertia of all machines.

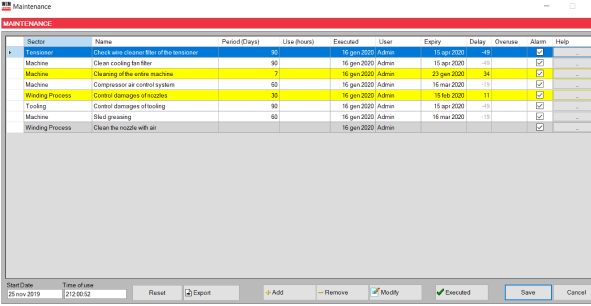

WaM-MCS has a lot of additional support functions. The integrated maintenance program to schedule and control all maintenance processes for the machine. The "smart power off" function, where you can turn off and on the machine, without losing position of all axis and cylinders.

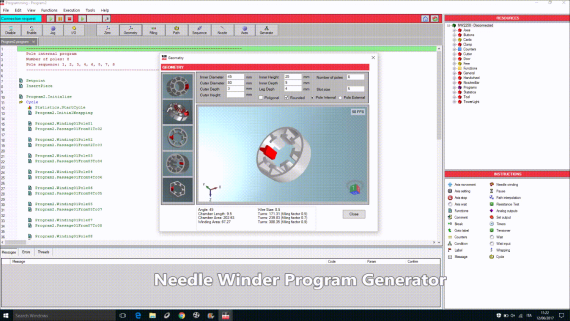

Faster ramp-up and better process control thanks to adjustable speed control. After step by step programming of new application, the speed of all servo motors can be easy adjusted and continuously regulated. Especially for motor winders (needle winder) WaM created an interactive “Program Generator”. Basic product's data can be entered in only 6 steps like, general design of stator, sequence of pole winding, etc. and after the generator create automatically the complete program. The application helps the user to program faster and more efficient.

For complex processes and big autolines with a lot of machines and very big differences of cycle time, WaM created a “Program Simulator”. The “real” process, incl. all handling functions, cylinders and sensors can be programmed on WaM-MCS. The process flow can be build up in a virtual machine, f.e. wire brakes, material flow, etc. can be simulated and the process could be tested.