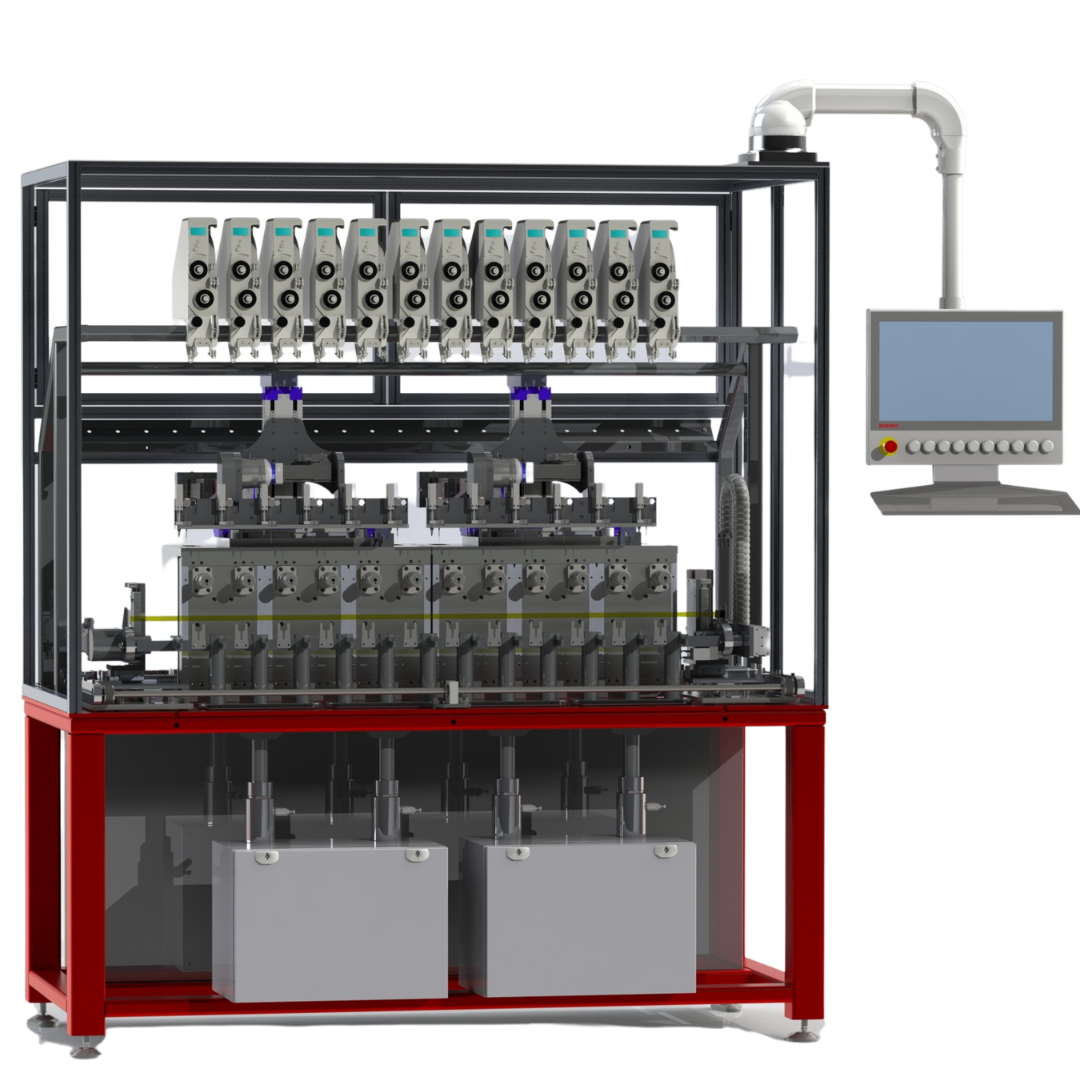

Linear winders

The modular designed WaM-LW linear winding machine series, works in fully automated process. The machines are prepared for stand-alone operation or integration in autoline. The loading/unloading shuttle system could be easily installed and guaranty no damages on bobbins.

Due to the reduced mass inertia by using multiple axis units the machines have between 11 to 20 servo motors with absolute axis position. EtherCAT/ProfiNET backbone and WaM-MCS software enables parallel use of axis units (gearing), precise positions, high repeatability, chain interpolation and adjustable speed of whole winding process for faster ram-up of your production.

WaM-MCS Windows based software installed on IPC. Modular software for control and program the winder. For more information see WaM-MCS.

Spindle concept is modular for winding 6/12/... or 8/16/24/... bobbins simultaneously, one (1) servo motor for two (2) spindles with 75mm pitch. Motor configuration could be adjusted to winding specifications (wire diameter and turns).

Installed on four (4) servo motors for X, Y, Z axis and Q axis (angle). The movement lengths of all axis is configurable, thanks to the modular concept. Modular single nozzle bar length of 600mm for 6/12 or 8/16 nozzles or multipal modular single bars. Optional parts are knife, scissors, bifilar, wire changer, etc.

Installed on four (4) servo motors for X/Y/Z/Q axis. Wire reject with venturi suction system and bin.

Installed on two (2) servo motors for X, Y axis. Standard module for stand-alone machine or integration in autoline, the length of standard Y axis is adaptable.

Closed loop tensioners up to wire size 0,8mm, integrated to WaM-MCS. Optional bigger closed loop tensioners for 0,3 - 1,2 mm wire diameter.